Editor’s note

This webpage currently provides only an introduction to this guide. Please download the PDF for the complete guide.

A manure management plan consists of balancing the use and/or reuse of organic material but, more importantly, nutrients — primarily nitrogen and phosphorous — and water. Water and nutrients are intertwined because water is the primary means by which nutrients are conveyed across and away from farms. On-farm nutrient and water management have become increasingly important in recent years. Nutrient losses reduce land productivity and/or increase operational cost for replenishment of lost nutrients. Nutrients in runoff degrade water quality in receiving bodies of water and have resulted in nearly $1 billion in negative economic impact every year just from tourism reductions across the U.S. Studies suggest that agriculture’s non-point source contribution to nutrient loads into the nation’s lakes, streams and rivers not only represents a large fraction of the overall load but is also one of the most difficult to address (“Agriculture | Chesapeake Bay Program,” 2020).

Addressing the challenges of decreased water quality resulting from nutrient loads requires a holistic approach that includes manure treatment technology innovation, advances in feed science and nutrition, optimization of soil and crop management, and creation of secondary markets that can drive revenue generation for manure-based, value-added products such as biogas and pelletized fertilizer. While all these aspects must be addressed, the separation and treatment technologies used at the point of generation can have the greatest impact. Individuals and organizations, both public and private, have accepted the challenge to develop innovative ways to address nutrient separation, removal and reuse.

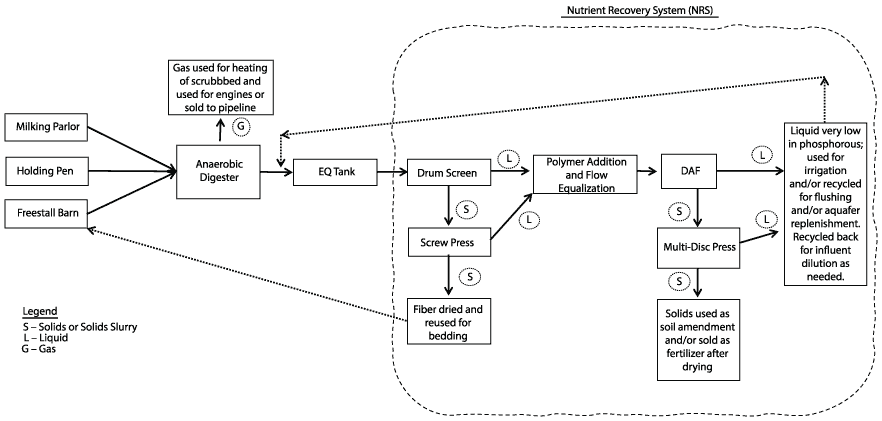

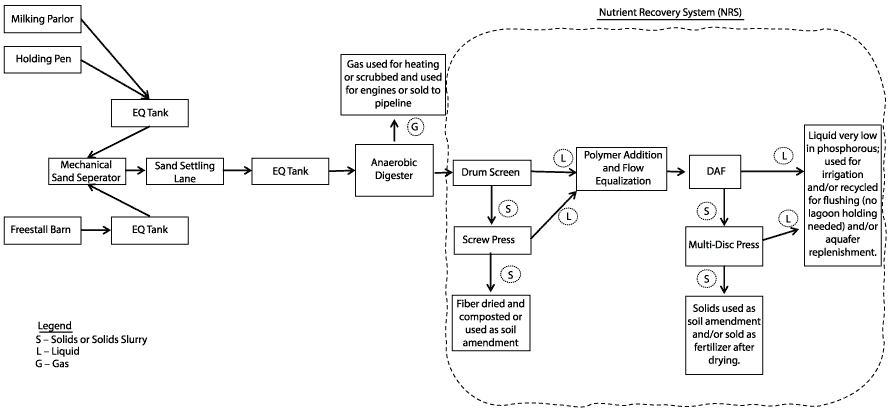

One system that has recently gained popularity because of its effectiveness is the combination of dissolved air flotation (DAF) and a multi-disk (MD) press to produce a nutrient-rich cake from a waste stream that has been conditioned by pre-screening coarse material (Figure 1). The DAF/MD combination is a physical/chemical process to separate solids and nutrients, primarily phosphorous and organic nitrogen, from impaired water.

The smallest of these systems is capable of processing several hundred thousand gallons of water per day and currently is intended primarily for medium- to large-scale dairies, generally producers with about 250 or more milking cows. One of these smaller systems could cost between $300,000–$400,000 (CapEx) and $30,000–$35,000 per year to operate (OpEx). The output of this size of system would include tea water that is high in ammonia and approximately 1,800 metric tons per year of phosphorous- and nitrogen-rich cake with approximately 25% solids content (“Evaluation of Nutrient Recovery Technologies,” n.d.).

Figure 1. Processes sketches of the Trident NRS system when applied to fiber- and sand-bedded dairies (top and bottom, respectively).

For the rest of this guide, download the PDF.