Electricity, one of the most versatile and widely used power sources, is used extensively on almost every farm. Farmers are so familiar with electricity that they may take electrical safety for granted. When this happens, accidents often follow. The National Safety Council reports almost 500 electrical fatalities annually. On average, more than 20 of these deaths are directly related to farming operations.

How much electricity is fatal? People can feel electrical currents at levels as low as approximately 1 milliamp (mA), which produces a slight tingling sensation. Increasing current levels above the 5 mA "let go" threshold can cause loss of muscular control, irregular heart rhythm and, finally, cardiac arrest. Five mA is only a small fraction of the current needed to power a 60-watt bulb, which draws about 1/2 amp, or 500 mA.

Electrical shock occurs when a person touches an electrically charged object at the same time they are touching another surface capable of conducting electricity to ground. A current then passes between the points of contact. The shock effects depend on the amperage, duration of contact and resistance of the pathway through the body. For example, damp skin is less resistant to current flow and permits greater shock effects. For this reason, you should work in a dry environment while handling electrical equipment.

The seriousness of a shock depends on the path the current takes through the body. For example, a small current passing through the heart is much more critical than a current passing between two fingers of the same hand. Testing for live current with one hand instead of two reduces the risk of a dangerous shock by making current less likely to flow through the heart.

Power hand tools

Portable power tools are one of the most frequent causes of death by electrocution on farms. Farm workers typically expose themselves to more electrical hazards than do workers in other industries. They frequently work alone, often operating electrical equipment in damp and dusty places with no one nearby to help in case of an accident. Farm work thus requires extra caution in using power tools. Follow these precautions:

- Never use any electrical hand tool that does not carry the Underwriters Laboratories (UL) Listing Mark. This mark indicates the tool has undergone extensive testing and has been found to be safe when properly maintained.

- Older tools with a two-wire design should be immediately upgraded to a three-wire system by qualified personnel. If your tool cannot be upgraded, discard it. Most power tools in use today have a three-wire system. This third wire serves as an emergency ground in case of an internal short or ground fault.

- Make sure the three-wire system is maintained through all adapters and extension cords. Adapters not properly connected to receptacle boxes make the ground fault wire ineffective.

- Never disconnect or carry power tools by their cords. This causes the cord's insulation to rapidly deteriorate. Inspect tool and extension cords routinely for fraying and other signs of deterioration. Repair or replace immediately.

- Consider using a ground fault interrupter (GFI). GFIs do not replace traditional protection provided by current isolation, insulation and grounding, but they are a backup if insulation or grounding fails due to age, abuse or mechanical breakdown. The GFI detects low levels of leaking current and cuts off power quickly at leakages greater than 5 mA.

Overhead lines

Too often, careless handling of farm equipment around electric power lines and utility poles leads to tragedy. Accidents can be prevented by insisting that hired hands and family members learn to survey work areas before using farm equipment. Make each worker determine that equipment will not come within 10 feet of power lines or power support equipment. Electrocutions can occur even if actual contact is not made with the line. The greater the line voltage, the farther electricity is able to "jump" to a ground conductor.

Recognize that power lines often follow property lines. As workers reach the end of the field and turn the equipment, there is a good chance power lines will be nearby. Power lines also are often near grain and equipment storage facilities. Be sure that paths from equipment storage areas to fields and from the fields to grain storage areas are safe routes. If you have any doubts that your equipment will clear a line, assume that it will not and take measures to avoid possible contact.

Crop storage equipment such as balers and stackers can be extended in height to exceed electric code clearances for power lines. When storing hay or baled straw, take precautions to be sure the stacking equipment will not come into contact with power lines.

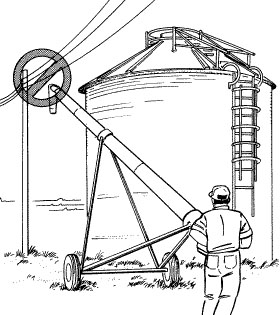

Portable grain augers are a leading cause of farm electrocutions. Lower augers when moving them from one bin to another. The operating height of an auger usually is greater than the height of power lines. If workers push one into a line by hand, they can be instantly electrocuted.

Stray voltage

Voltages greater than 1 volt disturb cattle, decrease dairy cow milk production and lower the average daily gain in beef cattle. If animals are exposed long enough to voltages greater than 25 volts, the voltage can be fatal.

Stray voltage on farms may stem from several sources. The voltage may occur predictably throughout the day, or it may occur randomly. These factors make controlling stray voltage a major problem.

On-farm stray voltages have been traced to the following sources:

- Ground faults on the farm.

- Voltage gradients across the ground or floor due to wires faulted in the earth.

- Electric fence wires shorting directly to equipment or energizing pipes and equipment.

Electrical motors and equipment can "short out" or ground fault to their outside casings. The severity can vary from a fault with no visible effect to a complete short circuit. When short circuits occur, all conductive materials, such as stainless steel milk lines and pipe fencing, become energized. Wood also can conduct electricity when it is wet. To correct the problem, faulty equipment should be repaired or replaced immediately by someone with proper training. The three-wire electrical supply line helps reduce the problem when the fault first occurs.

Voltage gradients through the earth or across a floor occur when an underground wire faults to earth. This often happens when the insulation of underground wires not rated for direct burial becomes damaged. Typically, the wires have not been buried at the proper depth. Underground wires buried many years ago are suspect, particularly if voltage gradients are detected in the earth. To correct the problem, the lines must be replaced with ones rated for direct burial.

Electric fence wires running through buildings can cause problems when building electrical wire is used. The maximum insulation rating of building electrical wire is 600 volts, which is not adequate insulation for the high-voltage pulse output of a fence charger. When this type of stray voltage is suspected, look for breakdowns in the insulation that could be causing a fault to metal equipment inside a barn. To prevent this problem, use insulated wire rated beyond the maximum voltage output of the fence charger.