The best method of handling residential sewage is through a properly designed and operated community or municipal treatment system. But many areas of Missouri have population densities so low that installation costs prohibit using community systems. In these areas, families must rely on individual waste treatment systems.

There are three generally recognized methods of handling wastes from a rural residence. They are the stabilization lagoon, the septic tank and the individual aerobic treatment plant.

This publication describes features and functions of the individual plant or package treatment system.

Individual package plants are a relatively new development in waste handling. Most units available today have been on the market less than 10 years. In spite of claims, the following general statements can be made about all individual package systems.

- Effluent, discharged fluid, from these systems is not clean water. It is a potential pollutant and must be handled appropriately.

- Each system has some mechanical parts that require periodic checks, maintenance and repair. There is no such thing as a completely trouble-free, maintenance-free sewage treatment system.

- Individual package treatment systems cost more to install and operate than other types of approved individual systems.

Aerobic process

All package treatment plants use the aerobic (with oxygen) digestion process to treat sewage. In this process, oxygen-using bacteria attack and break down the organic portions of the sewage into simpler inorganic compounds. Aerobic treatment is preferred because it is rapid and relatively odor free. It also provides greater solids reduction.

Septic tank systems rely on the anaerobic (without oxygen) breakdown process that is less efficient. It produces the characteristic septic odor.

Package plants maintain aerobic conditions by introducing air into the tank. This can be done in either of two ways. Some manufacturers use an external air compressor to bubble air through the sewage. Others draw air into the sewage by using either a pump or a stirring device that functions much the same as a high-speed food mixer or blender.

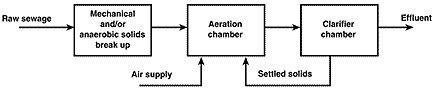

Figure 1. Treatment in a package plant.

Figure 1. Treatment in a package plant.

Treatment in the package plant is accomplished in three stages (Figure 1). In the first stage, raw sewage enters the system and larger particles are settled out or broken up mechanically to increase their surface area and make them more accessible to the aerobic bacteria.

Some systems make use of a separate anaerobic bacteria treatment chamber where anaerobic bacteria help break down the larger particles. Anaerobic treatment chambers require periodic pumping of sludge.

The second phase of the treatment consists of mechanical aeration. Oxygen-containing air is mixed and blended with mixtures of solids and liquid. During this period, aerobic bacteria reduce the sewage into simple compounds.

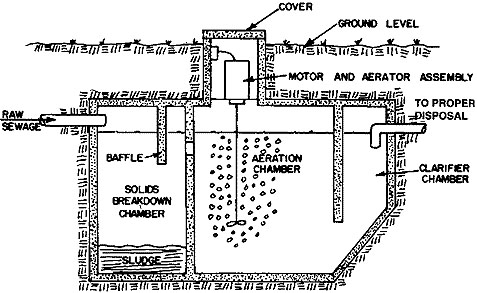

" Figure 2. Section of an aerobic chamber that uses an aerobic chamber to provide initial breakdown of solids. A stirring device provides the aeration.

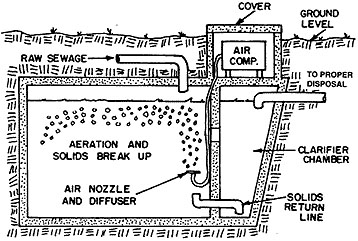

Figure 2. Section of an aerobic chamber that uses an aerobic chamber to provide initial breakdown of solids. A stirring device provides the aeration. Figure 3. Section view of an aerobic treatment system. The system uses the agitation of the aerobic chamber to break up solids in the raw sewage. An air pump or compressor provides aeration.

Figure 3. Section view of an aerobic treatment system. The system uses the agitation of the aerobic chamber to break up solids in the raw sewage. An air pump or compressor provides aeration.

The final step is the settling or clarification chamber. Treated sewage from the aeration process is emptied into this chamber where the heavier solids in the sewage settle. These solids are returned to the aeration chamber for further processing. The clarified liquid from this chamber either flows or is pumped out of the treatment plant (Figure 2 and Figure 3).

Plant location

Package treatment plants contain and process a material that is a potential health hazard. Care should be exercised in locating the plant so there is little danger of contaminating any public or private water supply. Plants should not be located within 10 feet of any building foundation, property line or pressurized water line. They should not be located within 50 feet of a well, water supply or stream. If possible, the treatment system should be located so that sewage can flow into it by gravity.

Sizing

Units are sized based on expected loading, their ability to mix oxygen with sewage, and a designed retention time. Most manufacturers specify capacity in terms of the number of people or number of bedrooms served. If a garbage disposal unit is used in the house, increase capacity by 50 percent. The Health Department recommends a minimum of 150 gallons per bedroom or 500 gallons per house.

Effluent disposal

Effluent from the package treatment plant is a potential pollutant. It contains nearly all of the nutrient materials in the original raw sewage, bacteria, and some amount of untreated or partially treated sewage. If it is indiscriminately discharged into the waters of the state, as defined by Missouri statutes, you may be held in violation of the law. There should be no direct surface discharge from one's property.

The most satisfactory method of effluent disposal is controlled application to a soil/plant filter. The plant growth can use the nutrients and soil bacteria to complete the purification process. Effluent discharged into a well-sodded, level terrace is one way to accomplish this.

For information on the design and installation of a settling terrace, contact your local MU Extension center or the Natural Resources Conservation Service.

If terrace installation is not possible, effluent may be collected in a sump area and distributed through a sprinkler system. This system provides a limited amount of irrigation during dry weather.

A third method is the subsurface disposal field. Design, construct and operate this system like a septic tank disposal field.

Maintenance

All sewage treatment systems require some degree of management and maintenance. Package plants are no exception. Regularly check to make sure that all parts of the system are functioning in good repair. Use your owner's manual to guide your inspection.

Many package plants require periodic removal of accumulated undigested solids. Use your inspection and manufacturer's recommendations to determine pumpout intervals and the amount to be pumped.

Caution

Use care in pumping out tanks during wet periods when soils are saturated. Partially empty tanks may float out of the ground unless precautions are taken to hold them down.

Before you buy

The National Sanitation Foundation (NSF) has a series of standards for construction and performance of individual aerobic treatment plants. It recommends that you consider only systems that meet or exceed these standards.

Some of the NSF standards are:

- Use durable products designed to withstand normal operating conditions.

- Include a visible or audible alarm system to warn of system failure.

- Use the system's specified power requirements. Most systems require the same amount of electricity as a frost-free refrigerator.

- Have complete instructions for proper installation and operation on hand.

- Make sure the system has a one-year warranty and an initial two-year service contract that specifies regular inspection calls and quality checks.

- Stock extra parts for temporary installation in the event that components of your system have to be removed to the dealer's shop or factory for repair.